Hordhac

Baabuurta casriga ah, dareemayaasha cadaadiska ayaa meel walba yaal. Waxay door muhiim ah ka ciyaaraan la socodka iyo xakamaynta nidaamyada muhiimka ah ee kala duwan, hubinta badbaadada baabuurka, kor u qaadista waxqabadka, iyo yaraynta qiiqa qiiqa. Tusaale ahaan, dareemayaasha cadaadiska saliidda waxay la socdaan cadaadiska saliidda si ay u hubiyaan in qaybaha matoorka si ku filan loo subkay, ka hortagga daalnimada iyo kulaylka. Dareemayaasha cadaadiska shidaalku waxay hubiyaan sahay shidaal oo deggan oo hufan, awood u siinaya mishiinka inuu ilaaliyo waxqabadka ugu fiican ee xaaladaha kala duwan ee wadista. Maqaalkani wuxuu bixiyaa dulmar faahfaahsan oo ku saabsan dareemayaasha cadaadiska baabuurta ee caadiga ah, oo ay ku jiraan shaqadooda, codsiyada, iyo arrimaha caadiga ah.

Mabaadi'da Nidaamka Matoorka

Dareemka Cadaadiska SaliidaDareemka cadaadiska saliidda wuxuu kormeeraa cadaadiska saliidda ee mashiinka si loo hubiyo in dhammaan qaybaha si ku filan loo subkay, sidaas darteed ka hortagga xirashada iyo kulaylka. Marka matoorku shaqaynayo, bamka saliidda ayaa saliid ka soo saaraya digsiga saliidda, wuxuu dhex maraa filtarka saliidda, wuxuuna u qaybiyaa habka saliidda. Dareemka cadaadiska saliidda, oo sida caadiga ah ku yaal meel u dhow block block ama filtarka saliidda, wuxuu furayaa wareegga oo dami nalka digniinta marka la gaaro cadaadiska saliidda ee ugu yar ee loo baahan yahay.

Dareemka Cadaadiska ShidaalkaDareenka cadaadiska shidaalku wuxuu kormeeraa cadaadiska nidaamka shidaalka wuxuuna macluumaadkan u gudbiyaa Module Control Engine (ECM). ECM waxay hagaajinaysaa soosaarka bamka shidaalka iyadoo ku saleysan xogtan si loo ilaaliyo cadaadiska ku habboon. Tani waxay hubinaysaa in matoorku uu helo shidaal xasilloon oo ku jira xaalado kala duwan oo wadista, ilaalinta waxqabadka ugu fiican. Haddii dareemaha uu ku guuldareysto, waxay u horseedi kartaa sahay shidaal oo aan degganeyn waxayna saameyn ku yeelan kartaa shaqada matoorka.

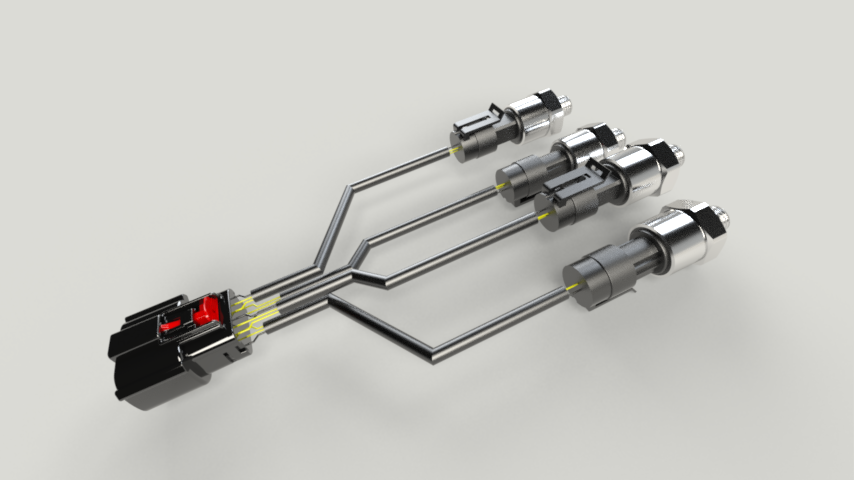

Kiiska Codsiga XDB401: Dhawaan, theXDB401 dareerahawaxaa lagu dhex daray nidaamyada hakinta hawada oof-wareenka iyo hawo-biyoodka si kor loogu qaado waxqabadkooda iyo isku halaynta. Dareemayaashani waxay bixiyaan cabbirada cadaadiska saxda ah ee saxda ah, iyagoo hubinaya in nidaamyada hakinta ay ilaaliyaan waxqabadka ugu wanaagsan ee xaaladaha kala duwan ee wadista. Mashruucani wuxuu muujiyay waxqabadka gaarka ah ee dareenka XDB401 ee jawiga qallafsan, isagoo si weyn u wanaajiyay xasiloonida baabuurka iyo raacitaanka raaxada iyadoo kor loo qaadayo cimriga nidaamka iyo ka jawaabista. Tusaale ahaan, mashruuc ku lug leh gaadhi wax qabad sare leh, dareemaha XDB401 ayaa loo isticmaalay in lagu kormeero oo lagu hagaajiyo cadaadiska nidaamka ka joojinta wakhtiga dhabta ah, hubinta maaraynta ugu fiican iyo raaxada.

Mabaadi'da Nidaamka Xakamaynta Hawada

Dareemka Cadaadiska DaalkaDareenka cadaadiska qiiqa wuxuu kormeeraa cadaadiska nidaamka qiiqa, isagoo gacan ka geysanaya xakamayntaDib-u-wareejinta gaaska daaqaya (EGR)iyo Naaftada Particulate Filter (DPF) dib u soo kabashada. Marka mishiinku soo saaro gaaska qiiqa, dareemaha ayaa ogaanaya isbeddelada cadaadiska oo u gudbiya macluumaadkan qaybta xakamaynta, taas oo hagaajinaysa EGR valve iyo habka dib u soo kabashada DPF si loo yareeyo qiiqa waxyeellada leh. Tani waxay muhiim u tahay kor u qaadista waxqabadka deegaanka ee baabuurka.

Mabaadi'da Hawlaha Nidaamka Badbaadada

Dareemka Kormeerka Cadaadiska Taayirka (TPMS): TPMS waxay la socotaa cadaadiska taayir kasta wakhtiga dhabta ah iyada oo loo marayo mowjadaha raadiyaha. Marka cadaadiska taayirka uu hoos uga dhaco heerka hore loo dejiyay, TPMS waxa ay kicisaa digniin, taasoo ku kalifta darawalka inuu eego taayirada. Tani waxay si weyn u wanaajisaa badbaadada darawalnimada iyadoo laga hortagayo shilalka ay sababaan taayirrada aan sariirta lahayn.

Dareemka Cadaadiska biriiga: Dareemaha cadaadiska bareegga ayaa ogaanaya cadaadiska haydarooliga ee nidaamka biriiga oo u gudbiya xogta qaybta kantaroolka biriiga. Marka uu darawalku riixo badhka biriiga, cadaadiska nidaamku wuu kordhaa, dareemaha ayaa si joogto ah ula socdaa isbeddelkan si loo hubiyo in braking wax ku ool ah uu ku jiro xaalado kala duwan. Tani waxay muhiim u tahay badbaadada inta lagu jiro bareegga degdega ah iyo wadista hoose ee dheer.

Mabaadi'da Nidaamka Raaxada

Dareemka Cadaadiska QaboojiyahaDareenka cadaadiska qaboojiyaha ayaa kormeeraya cadaadiska qaboojiyaha ee nidaamka qaboojiyaha. Marka nidaamku shaqeeyo, kombaresarada ayaa cadaadis saaraysa qaboojiyaha oo ku wareegaya qaboojiyaha iyo uumiga. Dareemuhu wuxuu hubinayaa in cadaadiska uu ku sii jiro xadka ugu fiican, isagoo siinaya saameynta qaboojinta ugu fiican. Goobaha kulul, tani waxay gacan ka geysaneysaa ilaalinta heerkulka gudaha ee raaxada leh.

Dareemka Cadaadiska Gudbinta: Dareemaha cadaadiska gudbinta ayaa kormeeraya cadaadiska hydraulic ee gudbinta tooska ah. Nidaamka hawo-mareenka gudbinta wuxuu xakameynayaa wareegyada qalabka iyadoo la hagaajinayo cadaadiska, hubinta isbeddellada siman iyo isku hallaynta gudbinta. Dareemuhu wuxuu u diraa macluumaadka cadaadiska qaybta kantaroolka gudbinta, kaas oo hagaajinaya valves hydraulic iyo xajin si loo gaaro waxqabadka wadista ugu fiican iyo gudbinta muddada dheer.

Gabagabo

Dareemayaasha cadaadiska ayaa door muhiim ah ka ciyaara baabuurta casriga ah. Fahamka shaqooyinka iyo codsiyada dareemayaasha cadaadiska kala duwan, waxaan si fiican u ilaalin karnaa oo aan ka faa'iideysan karnaa, hubinta badbaadada iyo waxqabadka gaariga. Fahamka mabaadi'da shaqada iyo arrimaha caadiga ah ee dareemayaashani waxay gacan ka geysataa garashada waqtiga iyo xallinta dhibaatooyinka iman kara, taas oo kordhinaysa cimriga gaadhiga iyo kor u qaadida khibradda wadista.

Waqtiga boostada: Agoosto-05-2024