alaabta

XDB103-9 Module Dareemka Cadaadiska Taxanaha

Astaamaha

1. Khaladka: 1% ka 0 ~ 8 5 ℃

2. Heerkulka buuxa ee kala duwan (-40 ~ 125 ℃), qalad: 2%

3. Cabirrada ku habboon dareemayaasha piezoresistive dhoobada caadiga ah

4. Cadaadiska xad dhaafka ah: 200% FS, cadaadiska dilaaca: 300% FS

5. Habka shaqada: Cadaadiska cabbirka

6. Qaabka wax soo saarka: wax soo saarka danab iyo wax soo saarka hadda

7. Walaaca cadaadiska muddada-dheer: <0.5%

Codsiyada caadiga ah

1. Dareemaha cadaadiska hawada ee gaadiidka ganacsiga

2. Dareemka Cadaadiska Saliida

3. Dareemaha cadaadiska bamka biyaha

4. Dareemaha cadaadiska hawada kombaresarada

5. Dareemka cadaadiska qaboojiyaha

6. Dareemayaasha kale ee cadaadiska ee goobaha baabuurta iyo warshadaha

Tilmaamaha shaqada

1. Xaddigan kala duwan ee korantada shaqaynaysa, wax-soo-saarka moduleka waxa uu ilaalinayaa xidhiidh siman iyo toosan.

2. Cadaadiska Ugu Yar ee Deminta: Waxa loola jeedaa korantada wax-soo-saarka moduleka ee barta cadaadiska ugu hooseeya ee kala duwanaanshaha cadaadiska.

3. Wax-soo-saarka Miisaanka-buuxa: Wuxuu tilmaamayaa korantada wax-soo-saarka moduleka ee barta cadaadiska ugu sarreeya ee kala duwanaanshaha cadaadiska.

4. Baaxadda Miisaanka-buuxa: Waxaa lagu qeexaa farqiga aljabrada ee u dhexeeya qiyamka wax-soo-saarka ee ugu sarreeya iyo dhibcaha ugu hooseeya ee cadaadiska cadaadiska.

5. Saxnidu waxay ka kooban tahay arrimo kala duwan, oo ay ku jiraan khaladka toosan, khaladaadka heerkulka, khaladaadka cadaadiska, khaladka heerkulka buuxa, khaladka heerkulka eber, iyo khaladaadka kale ee la xiriira.

6.Waqtiga Jawaabta: Waxay tusinaysaa wakhtiga ay qaadanayso in wax soo saarka uu ka gudbo 10% ilaa 90% qiimahiisa aragtiyeed.Dejinta Dejinta: Tani waxay matalaysaa soosaarka moduleka ka dib marka la maro 1000 saacadood oo cadaadis garaaca wadnaha ah iyo baaskiil wadida heerkulka.

Xaddid xuduudaha

1. Ka gudubka qiimaynta ugu badan ee la cayimay waxay u horseedi kartaa hoos u dhaca waxqabadka ama dhaawaca qalabka.

2. Wax-soo-saarka ugu sarreeya iyo qulqulka wax-soo-saarka waxaa lagu go'aamiyaa is-hortaagga u dhexeeya wax-soo-saarka iyo labadaba dhulka iyo tamarta korontada ee wareegga dhabta ah.

Waafaqsanaanta Electromagnetic EMC

Alaabtu waxay u hoggaansantaa shuruudaha baaritaanka EMC ee soo socda:

1) Faragelinta garaaca wadnaha ee ku meel gaadhka ah ee xadhkaha korontada

Heerka aasaasiga ah:TS ISO7637-2 Qaybta 2: Ku-meel-gaadhka korantada ee ku-meel-gaadhka ah ee ay weheliyaan khadadka sahayda oo keliya

| Puls No | Voltage | Fasalka Shaqada |

| 3a | -150V | A |

| 3b | +150V | A |

2) Faragelinta ka-hortagga ku-meel-gaadhka ah ee xadhkaha calaamadaha

Heerka aasaasiga ah:TS ISO 7637-3 Qaybta 3: gudbinta ku-meel-gaadhka ah ee korantada ee awoodda iyoisku xidhka inductive via khadadka aan ahayn khadadka Supply

Qaababka tijaabada: Habka CCC: a = -150V, b = +150V

Qaabka ICC:± 5V

Habka DCC: ± 23V

Fasalka Shaqada: Fasalka A

3) Xasaanadda shucaaca RF difaac-AL SE

Heerka aasaasiga ah:TS ISO 11452-2: 2004 Gawaarida wadooyinka - Hababka tijaabada qaybaha ee korantada Rabshadaha ka imanaya xargaha cidhiidhiga ah ee tamarta korantada - Qaybta 2: Xero gaashaman oo dahaadhan ”

Qaababka tijaabada: Anteenada Horn-soo noqnoqoshada Hoose: 400~1000MHz

Anteeno faa'iido sare leh: 1000 ~ 2000 MHz

Heerka tijaabada: 100V/m

Fasalka Shaqada: Fasalka A

4) Duritaan sare oo hadda jira difaac RF-BCI (CBCI)

Heerka aasaasiga ah:TS EN ISO 11452-4: 2005 Gawaarida wadooyinka - Hababka tijaabada qaybahakoronto khalkhal gelinta tamarta korantada ee dabaysha cidhiidhiga ah—Qaybta 4:Duritaan badan oo hadda socda( BCI)

Inta jeer ee soo noqnoqda: 1 ~ 400 MHz

Meelaha baaritaanka cirbadeynta: 150mm, 450mm, 750mm

Heerka tijaabada: 100mA

Fasalka Shaqada: Fasalka A

Shaqada wareejinta iyo jaantusyada sifada wax soo saarka

1) Shaqada wareejinta

VBAXA= Vs× ( 0.00066667 × PIN+0.1 ) ± (Cillad cadaadis × 0.00066667 × Vs) halka Vswaa qiimaha danab sahayda moduleka, unit Volts.

PINwaa qiimaha cadaadiska gudaha, unugga waa KPa.

2) jaantuska sifooyinka wax-soo-gelinta iyo soo-saarka( VS= 5 Vdc, T = 0 ilaa 85 ℃)

3) Qodobka khaladka heerkulka

Fiiro gaar ah: Cillad heerkulku waa toosan inta u dhaxaysa -40 ~ 0 ℃ iyo 85 ~ 125 ℃.

4) Xadka qaladka cadaadiska

Cabbirrada moduleka iyo sharraxaadaha biinanka

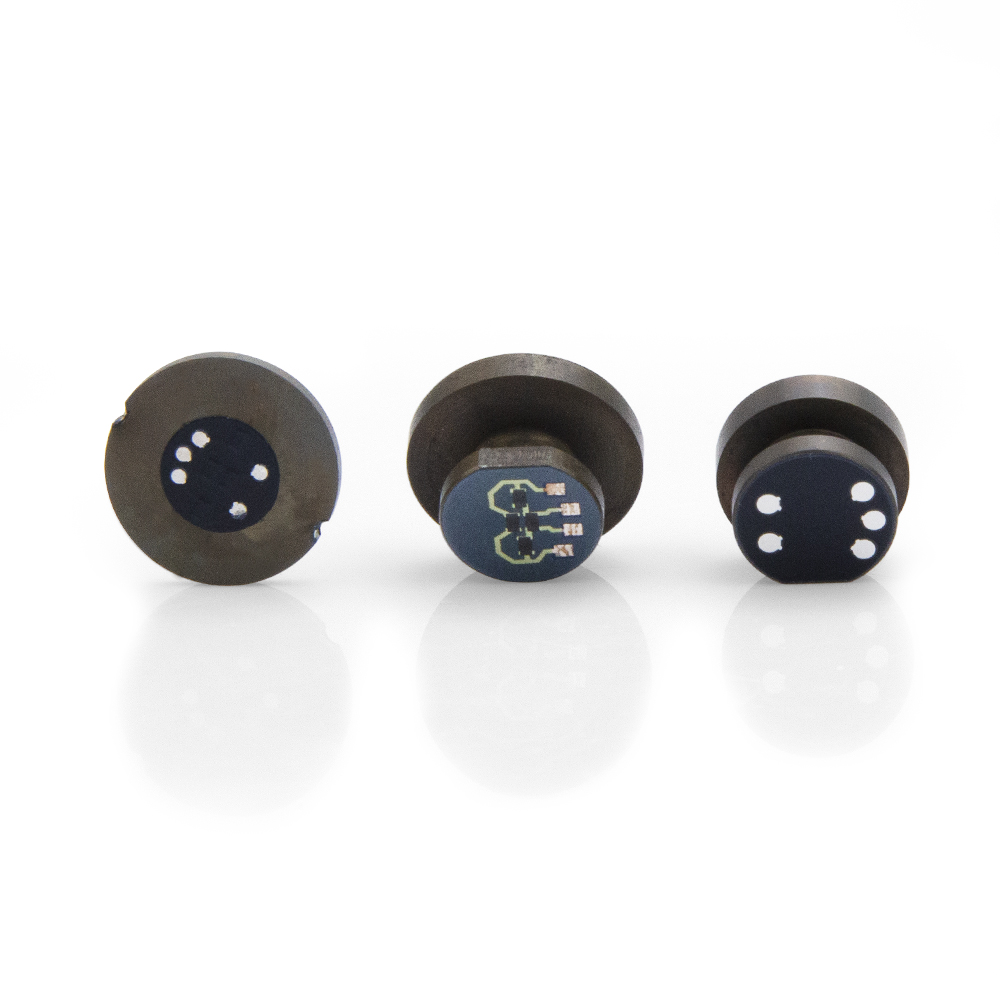

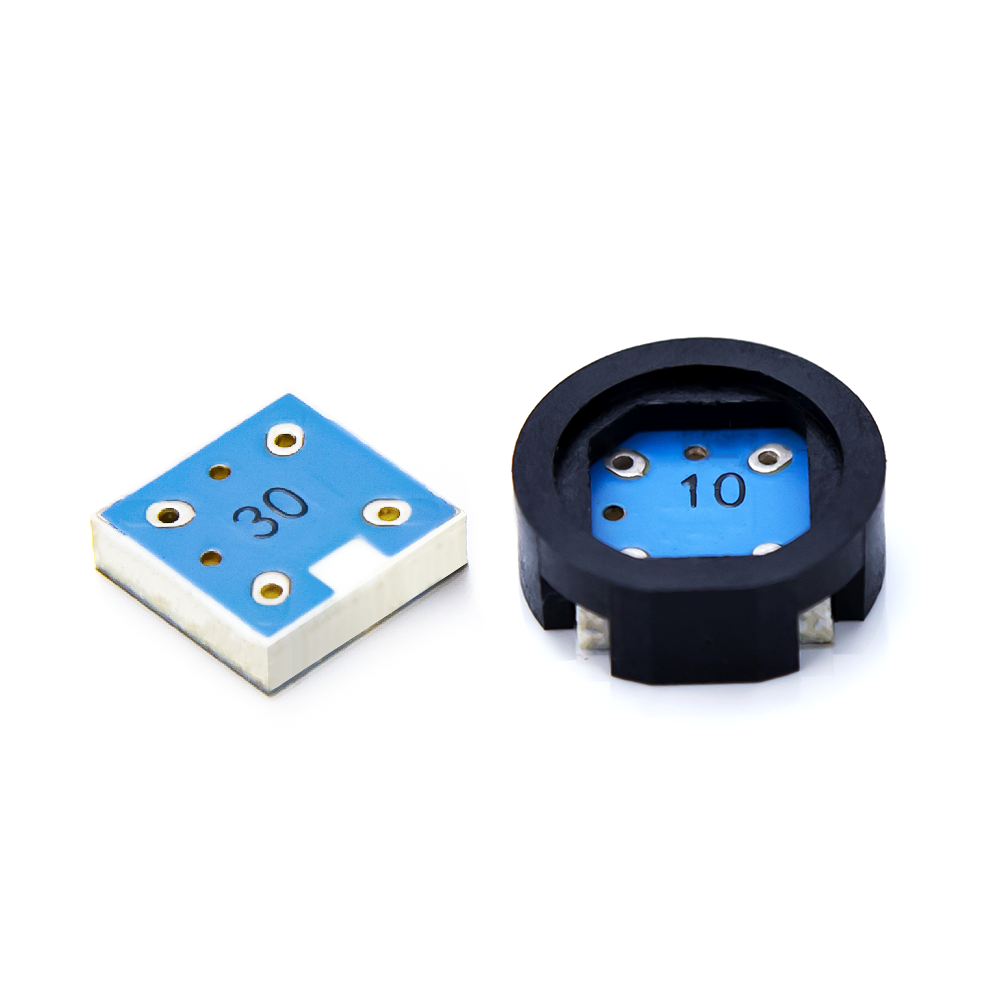

1) Dusha dareenka cadaadiska

2) Taxaddar isticmaalka Chip:

Sababo la xiriira habka wax soo saarka ee CMOS ee gaarka ah iyo baakadaha dareemayaasha ee ka shaqeeya wareegga qaboojinta ee chip-ka, waa muhiim in laga hortago waxyeellada iman karta ee koronto taagan inta lagu jiro kulanka alaabtaada.Maskaxda ku hay arrimaha soo socda:

A) Samee bay'ad badbaado ka hortag ah, oo ay ku dhammaystiran yihiin kuraasta shaqada ee ka-hortagga-static, sariiraha miiska, sagxadaha sagxadda, iyo xidhmooyinka gacanta ee hawlwadeenka.

B) Hubi dejinta qalabka iyo qalabka;Tixgeli inaad u isticmaasho birta alxanka-static-ka ah ee alxanka gacanta.

C) Isticmaal sanduuqyada wareejinta ka-hortagga-static (xusuusnow in caagagga caadiga ah iyo weelasha biraha ay ka maqan yihiin waxyaabo liddi ku ah joogsiga).

D) Sifooyinka baakad ee chip-ka dareemaha awgeed, iska ilaali inaad u adeegsato hababka alxanka ultrasonic ee wax soo saarkaaga.

E) Samee taxaddar inta lagu jiro habaynta si aad uga fogaato xannibaadda marinnada hawada ee chip-ka.